Design & Manufacture of Complex, Lightweight Castings for the Automotive Industry

World-Leading Powertrain & Body In White (BiW) Casting Specialists

Combining industry-leading advanced foundry technology and extensive experience to innovate casting manufacture and deliver geometrically complex cast parts for high-performance and lightweight applications for the Automotive industry worldwide.

Speak to an expert

Discuss your project with a casting development engineer today!

The Complete Design & Manufacturing Hub For Creating Complex, Lightweight, High-Integrity Automotive Castings

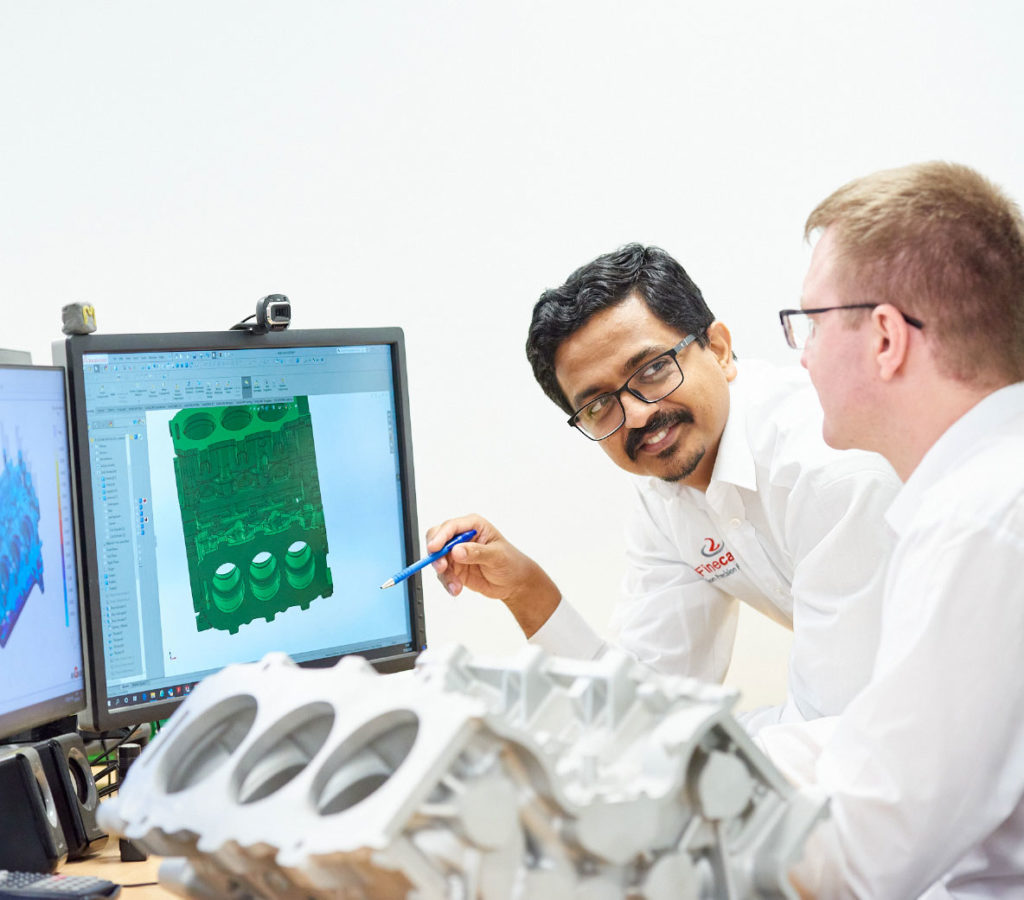

At Finecast, we develop, engineer, and manufacture high-precision complex sand cast components for the automotive industry worldwide. We are an industry leader in sand casting and continue to pioneer new innovations in sand casting production, sand media and material optimisation, integrity testing and casting validation to help shape the future of vehicle production.

We produce a wide range of high-integrity, fully machined sand cast powertrain components, including engine blocks, cylinder heads, transmission housings, turbine housings, compressor housings, exhaust manifolds, and EV cast components such as electric drive units and battery enclosures, as well as lightweight, high-strength, thin-walled body-in-white (BiW) structural parts.

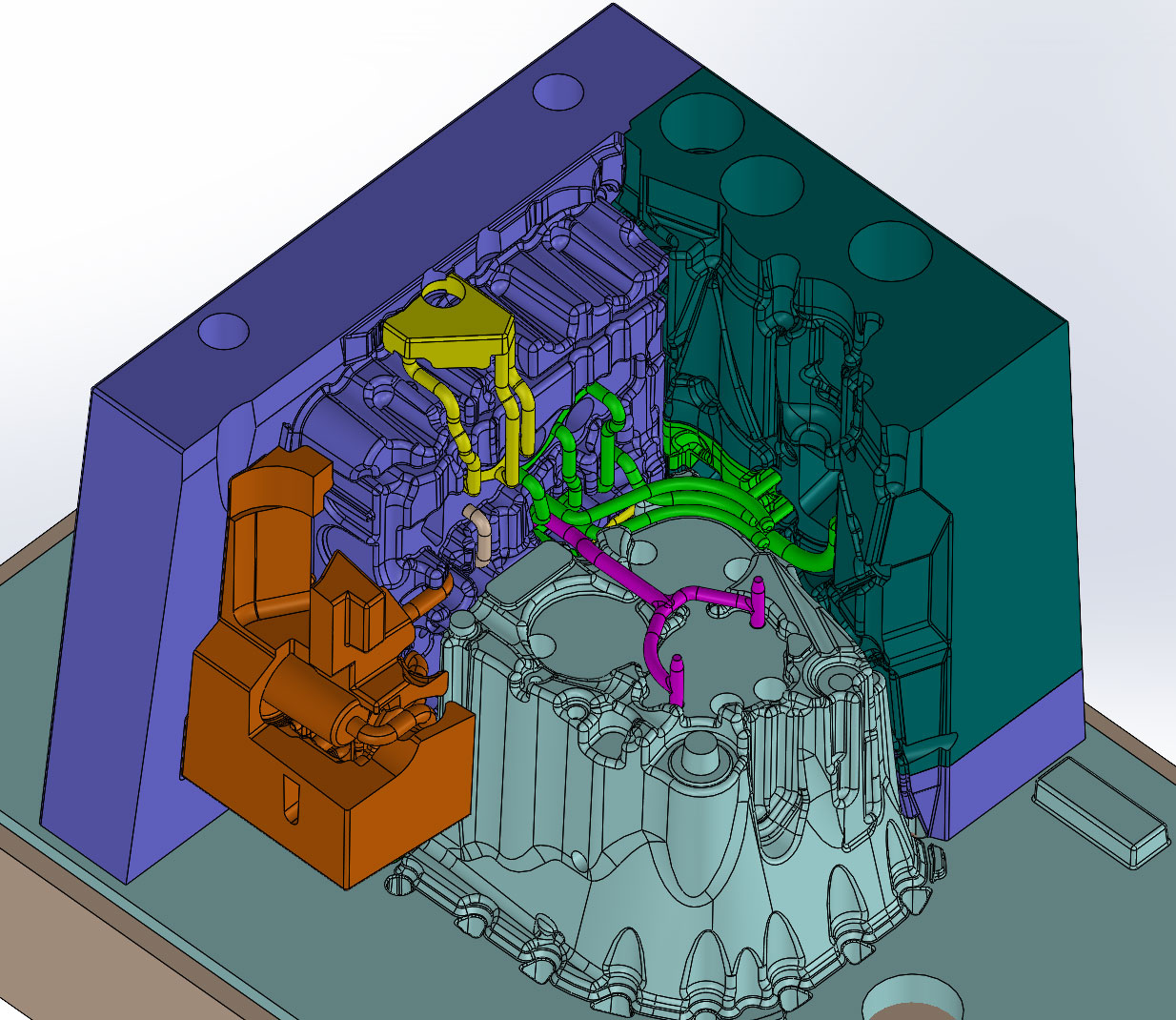

Finecast offers a full-service one-stop solution for automotive components from our state-of-the-art facility. We provide a unique technologically advanced manufacturing process, which includes virtual MAGMASOFT® 32 Core casting simulation, 3D sand printing, foundry tooling, rapid prototyping, low/medium-volume series foundry, cast component integrity validation, 5-axis CNC machining and machined component CMM dimensional validation.

Our advanced facility, technical processes and engineering experience enables us to deliver each and every component exactly to your specification, meeting tight lead times and to the very highest quality standards.

Find out more about our advanced facility, processes and latest automotive casting projects and see why we are the perfect partner for your next project.

Stage 2

Precision Sand Casting For Powertrain & Body In White Components

> Rapid Prototype Castings

Our purpose-built prototype facility offers the flexibility to rapidly manufacture and qualify superior quality, technically challenging cast products to provide proof of concept, integrity testing and validation before committing to large production volumes.

We achieve this by utilising ‘Magmasoft® 32 Core’ the industry-leading Virtual Simulation Software, our in-house Materials Lab, 3D Sand Printing Centre, Advanced Low/medium Series Foundry, Cast Validation Lab (CT Scanning/GOM/Creaform) and Dimensional Validation Lab (CMM) combined with our extensive automotive engineering experience.

Our unique rapid prototyping process can produce high quality automotive components within weeks, enabling our customers to considerably shorten product development time.

> Lightweight Engineering

Finecast is pioneering the development and manufacture of lightweight high-strength aluminium structural components for the automotive industry.

We are now pushing the boundaries by producing large sized, highly-strong, highly-ductile and durable structural body in white (BiW) automotive parts with consistent wall thicknesses of down to 2.5mm and up to 2 metres in length.

From extensive material research and innovation in lightweight powertrain and body structures we have developed and refined high silicon aluminium alloy series prototype and low volume sand cast production that replicates the geometry and mechanical properties of series in high pressure die castings.

> Low/Medium Volume Series Sand Casting Foundry

Our in-house foundry allows us the flexibility to support initial production phase builds up to scheduled mass production volumes up to 5000 units.

We support low/medium volume production of automotive components where high cast and mechanical integrity and surface finish quality is critical, the vast majority of the castings we produce are for the motorsport, sports-car, luxury and electric vehicle markets.

Our continued investment into advanced robotic foundry equipment includes automated mixers, high-speed mould filling and closing stations that offer efficient repeatable processing for components up to 2 msq.

We have also invested in the latest thermal sand reclamation system allowing us to reclaim up to 95% of the sand we use in our foundry, making our sand casting manufacturing process more efficient and significantly lowering our carbon footprint.

In addition, we can also optimise our sand quality during the thermal reclamation process, resulting in exceptionally high-quality castings with superfine surface finishes.

Stage 3

Testing & Validation For Powertrain & Body In White Castings

> Chemical, Composition & Mechanical Analysis

From our in-house laboratory we use our specialist laser spectrographic equipment to ensure full traceability of process parameters to validate the chemical, composition and mechanical analysis for all types of sand media and casting material.

Our team of MA-qualified metallurgists will perform spectrographic analysis of the melt sample throughout production to ensure chemical composition is meeting the customers exact engineering specification.

This comprehensive approach to spectrographic analysis means we consistently produce repeatable, defect free, high integrity automotive castings every time.

We have a wealth of experience in this field which allows us to develop unique alloy compositions designed for lightweighting, ductility, durability and thin-walled parts.

From our onsite heat-treatment facility we can treat large castings to improve mechanical and physical properties, our largest solution furnace volume is 11.56m³ (2.15m x 2.15m x 2.5m). We use a range of water and polymer quench to control distortion and residual stresses in all components and in accordance with customer requirements.

> Geometric Optical Measurement

Our advanced inspection and validation process using optical scanners (GOM/Creaform) guarantees dimensional accuracy and stability by creating a 3D model which is superimposed onto the parent automotive part CAD model.

The process allows for strategic alignment between the casting and machining datums, ensuring we deliver consistently accurate machined castings exactly to the customers specifications.

> NDT – 2D Radio Tomography & 3D Computer Tomography

It is critical for automotive parts to be high-integrity and defect free. Our powerful GE Seifert X|Cube 320KV CT Scanning System allows us to offer the very best non-destructive testing (NDT) in the UK and efficiently identify micro porosity, small incipient cracks and surface imperfection in all types of automotive components whether it be an engine block or a structural BiW part.

> Pressure & Leak Testing

The integrity of our automotive castings are checked and verified by using air decay or hydrostatic pressure testing. We are able to verify core complex components with intricate oil galleries such as engine blocks and cylinder heads by repeating various leak rates and test pressures.

Stage 4

CNC Machining For Powertrain & Body In White Castings

> Fine-Machine, Close Tolerance Complex Components

Our state-of-the-art machining division offers a fully integrated service. Equipped with the latest High spec 5-axis Mazak CNC machining centres and driven turning machine tools, combined with our team of expert machining engineers enables us to CNC machine repeatable, close tolerance, complex geometric components, in a range of different material grades.

Our machining division has extensive experience in producing a wide range of geometrically complex cast products for the automotive industry including, engine blocks, cylinder heads, gearbox housings, turbochargers, battery trays, electric drive units, structural BiW parts as well as a wide range of high performance components.

Stage 5

Dimensional Validation For Powertrain & Body In White Machined Cast Components

> Machined Component Dimensional Validation

Our in-house metrology laboratory has the very best inspection and validation capabilities including 3 CMM’s (coordinate measuring machines) and advanced programming software with programmable probe stations to measure components upto 2 metres.

We are also able to accurately and rapidly validate surface finishes, contours and angle measurements with our industry leading ‘Hobson Taylor Talysurf’ measurement instruments.

This advanced technology in combination with our highly experienced inspection team enables us to deliver automotive parts that meet our customer requirements including CPK Indices, SPC analysis, full ISIR and FAIR reports.